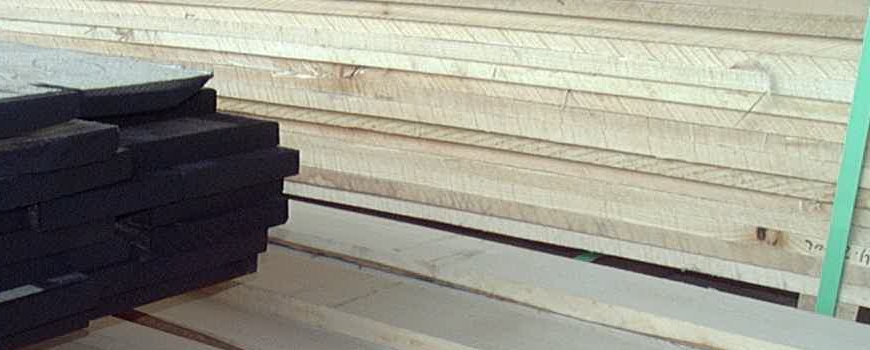

For the production of R - stick drumsticks, we use only the highest quality materials, the selection of which we ensure exclusively. We never buy from external suppliers. They lack our knowledge and are unable to meet our strict requirements for quality and workmanship. These are so specific that we have to take care of them ourselves.

Quality resolution:

- for hornbeam drumsticks in all rows we use a specially selected material, where we check each french fries before production and discard the corresponding ones.

- for the production of hickory drumsticks in the highest row, we similarly check and take over hickory chips.

- for hickory drumstickss in B class we use material that has not passed our quality control for the highest range. We do B class only in limited quantities.

- We produce an economical range of Superstick sticks from unsorted material, where the term "unsorted" means that we do not perform quality control during production and process the entire batch. We only exclude french fries with an obvious defect. We do the economic series only in limited series.

- for the production of advertising (merchandise) sticks, we use hornbeam, which we discarded during quality control. These sticks are designed for advertising and promotional purposes and the emphasis is mainly on their appearance.

HICKORY

Hickory is the most widely used material from North America. It is popular for its toughness, ideally combining weight, strength and durability. It has excellent reflective properties, absorbs vibrations and dynamic shocks generated during the game well. It is very resistant to breakage, abrasion by cymbals and longitudinal splitting. It is suitable for all styles and especially where it is necessary to use more force and dynamism in the game. For the production we use wood originating exclusively from the Right hickory group, and only selected types suitable for the production of sticks.

HORNBEAM

Hornbeam has universal use. It is popular for its dynamics, more agile reaction and better control over the mallet. When playing cymbals, it can emphasize mainly low and high tones, while giving a distinctive ringing sound. It is characterized by considerable homogeneity of wood, strength, relatively good rigidity, poorly absorbs dynamic shocks. Compared to hickory, it is 8 -10% lighter and, compared to it, it also has a shorter service life, which is, however, offset by a very favorable price.

Alternative materials:

they are visible on the e-shop only when we are doing a limited series, otherwise they are hidden by default.

MAPLE

It is relatively light - compared to hickory by about 15 - 20%. Its resistance is lower, it suffers more from abrasion by cymbals and fracture, it absorbs dynamic shocks and vibrations relatively well. It is popular with some drummers for its weight in relation to the strength of the mallet, for excellent handling and for quiet and technical playing. We do not use common types of maple for production, because they have poor dynamic properties and low strength. We use one less known species, which with its properties surpasses similar material originating from America.

LOCUST

Tough and very flexible material, highly resistant to puncture. It absorbs mechanical shocks well, its resistance to abrasion by cymbals is quite average, when playing over the edge of a snare, or flat on cymbals, it tends to peel after years. It is about 10% lighter than hickory. We use this material mainly for the production of limited economic series of sticks.

Other materials:

Alternatively, we occasionally test other less common woody plants, which, however, have very interesting properties and their parameters sometimes surpass commonly used materials. We have selected about 6 types of other materials - so maybe sometime in the future you can expect a pleasant surprise ......